When Seals Breathe Too Much: The Role of Vapor Transmission in Emissions and Product Integrity

Aboveground Storage Tanks (ASTs) are the backbone of the energy and chemical supply chain, quietly doing their job in tank farms, terminals, and refineries across the world. While operators are vigilant about many threats – corrosion, leakage, pressure imbalances – there’s one factor that often escapes attention until it causes a costly failure: Moisture Vapor Transmission (MVT).

Though it occurs at the molecular level, the effects of MVT are anything but minor. In fact, when it comes to tank seal performance, MVT is directly linked to elevated emissions, stored product contamination, and regulatory non-compliance. It’s a silent process with significant consequences, and it deserves a place at the forefront of every tank operator’s maintenance and materials strategy.

What Exactly Is Moisture Vapor Transmission (MVT)?

Moisture Vapor Transmission is the measure of how much vapor passes through a material over a given time and area. In the case of ASTs (particularly internal floating roof [IFR] tanks) the focus is on how vapor penetrates the vapor barrier fabric and other components used in primary and secondary seal systems.

AST seals are designed to isolate the vapor space from environmental conditions. When MVT is not tightly controlled, moisture from humidity, rain events, or temperature-driven condensation can slowly penetrate these seals. While this process may go unnoticed for months or even years, it steadily undermines the performance of the tank.

The MVT – Emissions Connection

One of the primary functions of floating roof seals is vapor containment – keeping volatile organic compounds (VOCs) from escaping into the atmosphere. When moisture permeates the seal material:

- It can displace product vapor and allow it to escape past the seal (increasing your emissions without you knowing).

- It accelerates material degradation, reducing the effectiveness of containment and seal contact with the tank shell.

This creates a situation where seals no longer hold a proper vapor barrier, leading to increased emissions and lost or contaminated product.

Even small increases in vapor loss can have significant implications. According to the EPA, floating roof tanks are a major source of VOC emissions in the petrochemical sector. A compromised seal may result in non-compliance with emissions regulations (like the EPA’s new 40 CFR 60 Kc), trigger environmental penalties, and put terminals at risk of scrutiny from regulatory agencies.

Contaminating The Product You’re Supposed To Protect

While many operators focus on emissions losses, an equally critical issue is product contamination, especially in tanks storing fuels, specialty chemicals, or water-sensitive materials. When moisture enters the tank via permeable seal materials additives or blends may be compromised, impacting downstream performance.

This is particularly important in today’s market, where fuels may include ethanol or bio-additives, which absorb more moisture than pure hydrocarbons. Even minor moisture ingress can change the product’s chemistry, leading to off-spec batches, customer rejections, or costly filtration and reprocessing.

Not All Fabrics Are Cut From The Same Cloth

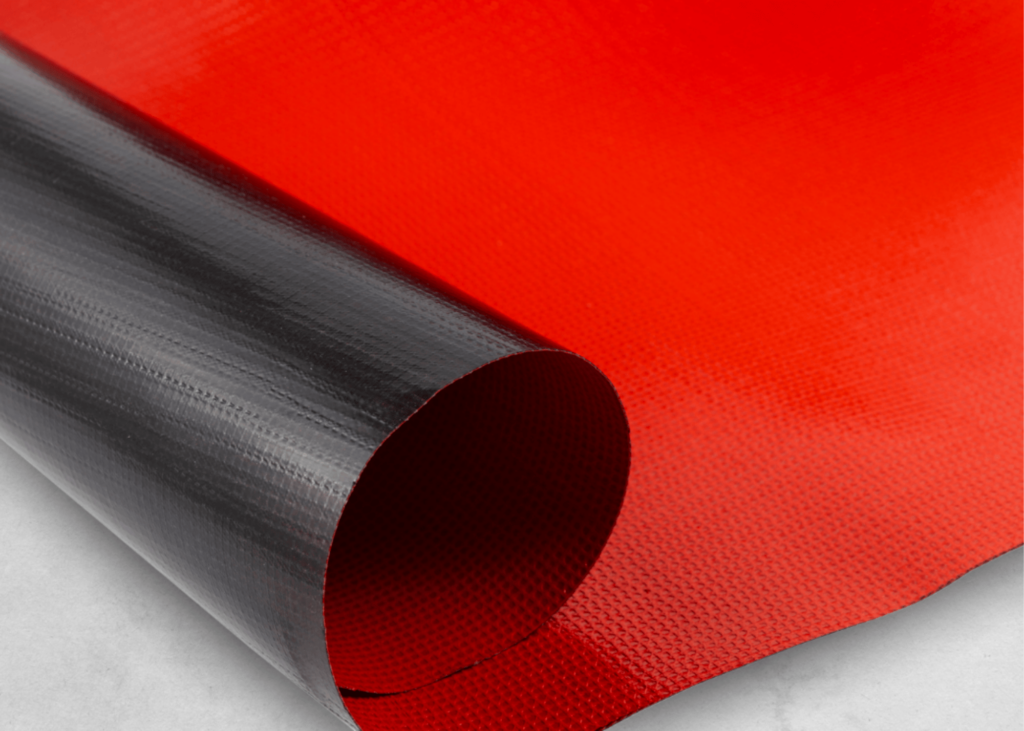

Most tank seal fabrics in the industry are elastomer- or polymer-based composites. These materials vary widely in their MVT performance depending on thickness, polymer type, reinforcement method, and manufacturing process.

However, many commonly used seal materials in the industry are not tested for MVT – or are tested using irrelevant standards that do not reflect real-world tank conditions.

That’s why ASTM E96 (specifically E96/E96-16) is the standard to look for. This test method determines the vapor transmission rate (VTR) in controlled conditions and helps compare materials head-to-head. Operators should request MVT test data from material suppliers and understand that a low MVT value is not just a bonus – it’s a requirement in high-performance seal applications.

Real-World Repercussions

Let’s consider two tanks, side by side, both storing gasoline with ethanol additives:

- Tank A uses a high-performance, low-MVT fabric designed for emission and moisture resistance, like Mesa ETP’s Armor Fabric™

- Tank B uses an older legacy material with no tested MVT rating, like the industry standard Teflon®.

Five years in, Tank A is still within emissions limits, with a clean product sample and a seal showing no visible deterioration. Tank B, meanwhile, is reporting elevated VOC emissions, signs of corrosion, and a contaminated product sample. Operations flags the tank for early maintenance, leading to downtime, cleaning, and a costly product loss.

What failed in Tank B? The material. And more specifically: MVT was ignored when the seal was specified.

Pro Tip: Check the last time your seals were tested for emissions. Many tank owners and operators are finding that their legacy Teflon® seals have been leaking without them knowing.

A Call for Smarter Material Standards

As the AST industry continues to evolve – with more stringent environmental regulations, tighter environmental reporting, and a push toward longer-lasting infrastructure – the role of material science in seal design cannot be overstated.

By prioritizing low vapor transmission rates in seal material selection, operators and engineers can:

- Reduce VOC emissions

- Protect product integrity

- Extend the service life of seals

- Lower maintenance frequency

- Achieve greater regulatory compliance

And perhaps most importantly, they move from a reactive maintenance mindset to a proactive reliability strategy – one that guards against failures before they happen.

Final Thoughts: Think Beyond the Obvious

Vapor transmission is easy to overlook – it’s invisible, slow-moving, and doesn’t sound as dramatic as a leak or a rupture. But over time, its impact on emissions, product quality, and system longevity can be just as damaging.

As the saying goes, “an ounce of prevention is worth a pound of cure.” In the case of ASTs, that prevention starts with specifying seal materials that are designed – and tested – to keep moisture where it belongs: outside the tank.

Have more questions about MVT, or want a free seal fabric comparison for your tank?

Monthly Archives

- November 2025

- October 2025

- June 2025

- May 2025

- March 2025

- February 2025

- December 2024

- November 2024

- May 2024

- April 2024

- January 2024

- October 2023

- August 2023

- May 2023

- April 2023

- June 2022

- May 2022

- September 2021

- July 2021

- January 2021

- August 2020

- July 2020

- May 2020

- April 2019

- January 2019

- November 2017

- October 2017

- July 2017

- June 2017

- May 2017

- April 2017

- February 2017

- November 2016